Monday, November 30, 2009

Framing A Fake Roof Girder

Sunday, November 22, 2009

Main Stairway Finished

I used my table saw to cut the dadoes in the stair treads and the risers. I don't have dado blades, so I just make several passes; moving over 1/16" each time.

The top of the riser fits into the bottom of the stair tread, and the back of the stair tread fits into the bottom face of the next riser.

Wednesday, November 18, 2009

Groundwork

Monday: It snowed over the weekend, so we spent this class period moving snow off of the piles of materials we had outside.

Tuesday: We moved the tool shed using 6 inch steel pipes and a pint of elbow grease. After sweeping and shoveling; we worked into the night pushing the rolling shed to its new home 50ft away.

Wednesday: Since we are still at the shop we cleaned up the equipment cage, assembled concrete forms for our deck pilings, and cut and bent re-bar to strengthen them.

Friday: We reviewed blueprints to get a list of materials we would need to cut so we can frame the first floor after the groundwork is finished.

Monday, November 16, 2009

Efficient Framing for House Plans

- use 2x6 wall framing at 24" o.c. (in lieu of 16" o.c.)

- use 1" rigid foam insulation in lieu of traditional sheathing

- eliminate headers where they are not necessary structurally - where they are necessary size them properly (it is common practice to use the same size header throughout)

- eliminate all the corner framing - let the drywall hang loose or use clips

- use header hangars in lieu of jack studs

- eliminate one of the top plates

Friday, November 13, 2009

Insulation

-Monday: We added foam insulation to the sides of the house, the foam is 2" thick, and when added onto the ARXX blocks it gives us a total of 4" of insulation on the outside.

-Tuesday: Added Soprema water proof insulation on top of the foam to keep the water out.

-Wednesday: Veteran's Day, no school.

-Thursday: Added dimple matting on top of the waterproofing.

-Friday: Clean up day, made sure everything was ready for the snow that is scheduled for the weekend.

The foam insulation that was added to the sides.

Design Challenge for a 2000 SF House Plan

- Programming

- Schematic Design

- Design Development

- Construction Documents

- Modest plan size - as close to 2000 square foot as possible.

- Open floor plan - Living, Dining and Kitchen spaces very connected with each other.

- Mudroom with space for hanging coats and sitting for putting shoes on.

- Laundry space should be on the main floor.

- A main floor master bedroom with walk in closet and bath. The bath should have a walk in shower, but not necessarily a tub (the days of the jacuzzi tub seem to be over).

- Spaces that are functional, but not over sized.

- A reasonable sized entry porch.

- A screen porch with spaces for eating and sitting.

- A main floor powder room.

- Possibly a den or away room - if space allows.

- An attached 2 car garage - possibly with some additional storage space.

- 2 additional bedrooms on a second floor.

- A shared bathroom for the 2 upstairs bedrooms.

- A basement that could allow future expansion space.

- Beautiful home but not overly complex. Should be reasonably economical to construct. The house plan should be simple, yet unique.

Wednesday, November 11, 2009

XHouse2 Construction Prints available starting Yesterday!

We are very happy to announce that the Construction Prints for the XHouse2 are complete, and available from the catalog page.

This is the first design from our summer '09 push to post new designs. It took a little longer than hoped to get the first Construction Print set posted, but that always seems to be the case. Next we are going to focus on the XHouse3, as we see its moderate size and compact footprint being appropriate for the times. Look for it in early 2010.

The XHouse2 at lamidesign.com/plans

Stairway Progress

Monday, November 9, 2009

Stemwall Pour

Sunday, November 8, 2009

Electrical Service Panel

I've used 2" PVC conduit to go down from the meter base and through the wall to the electrical panel. There are three 2/0 gauge wires that run through the conduit. The wire is very stiff and difficult to work with, and it took me an hour of pushing and pulling and cursing to get the three wires through the conduit.

The center wire (white tape) is the neutral wire and the other two are the "hot" wires.

Oh yes... there is no power on any of this yet. I wouldn't be doing any of this if there were. Once I have everything installed the electrical inspector will have a look at it, and if he approves it then the power company will come and install my electrical meter and hook me up to the grid.

Friday, November 6, 2009

How to design a bay window!

On the other hand my recent trip to the Napa Valley area reminded me that the bay window can be a beautiful design element when properly integrated with the architecture of the house plan. Here are a few examples on mostly craftsman style houses - all discovered in the town of Napa.

On the other hand my recent trip to the Napa Valley area reminded me that the bay window can be a beautiful design element when properly integrated with the architecture of the house plan. Here are a few examples on mostly craftsman style houses - all discovered in the town of Napa.

Wednesday, November 4, 2009

Second Landing Done

Tuesday, November 3, 2009

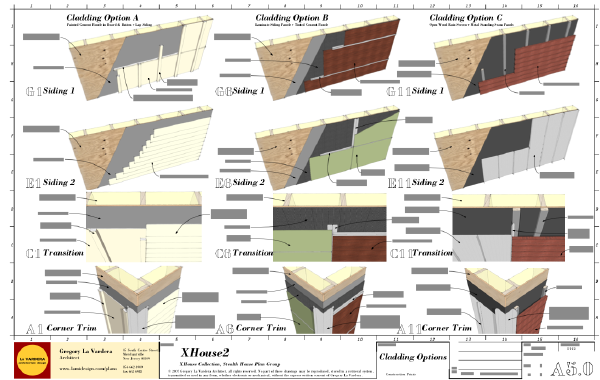

XHouse Cladding Options

We've completed a drawing sheet showing a range of 3 cladding options for the XHouse series of designs. This will be included in each plan set for the XHouse collection.

Our Construction Prints have always described a range of siding materials in the Owner's Choice portion of the Material List. The idea here is to show a range of siding options, from simple to more complex which would be specific to the designs. They also range in cost from less to more expensive, but our plans have always been about an open ended design that allowed the home owner to tailor the build to their budget and taste.

The first option is for painted cement siding panels a combination of board & batten and lapped siding patterns. This is the default siding pattern that is shown on our Original Collection designs. The XHouse designs also lend themselves to this cladding option as they typically include two different siding patterns on the walls. This is an accessible option as there is nothing tricky or unfamiliar about the installation, and most contractors will be completely familiar with this.

The second option is for a combination of laminate siding panels and through tinted cement siding panels. In this case the laminate siding panels are shown in a wood grain pattern. There are many siding panels available with this appearance, some with a resin impregnated wood surface, and others with a printed plastic laminate face - think formica for the walls of your house. The installation is shown for 24" high panels with metal flashed horizonal joints. This is not an inexpensive material but is quite handsome. The cement siding in this case is a through tinted material that requires no paint. The installation is a grid of panels with joints backed by metal flashing - no battens. This includes the addition of a drainage layer behind the siding for superior performance.This very siding scheme was featured on the 0751 RS House, and you can see it in those illustrations.

The third option is a combination of open wood rain screen cladding and standing seam metal panels. The rain screen is a recently popular look on many modern houses, and this is in fact the cladding scheme we have been featuring in the illustrations of the Xhouse Series designs. There are a range of woods that can be used for the siding planks, but the key component of this system is the vapor permeable water barrier that provides the final weather barrier for the wall system. The metal cladding is used on smaller portions of the XHouse designs, but is an important part of the overall look of the houses.

Just a little bit more work to complete on the XHouse2 Construction Print set. Look for the official intro before Thanksgiving.